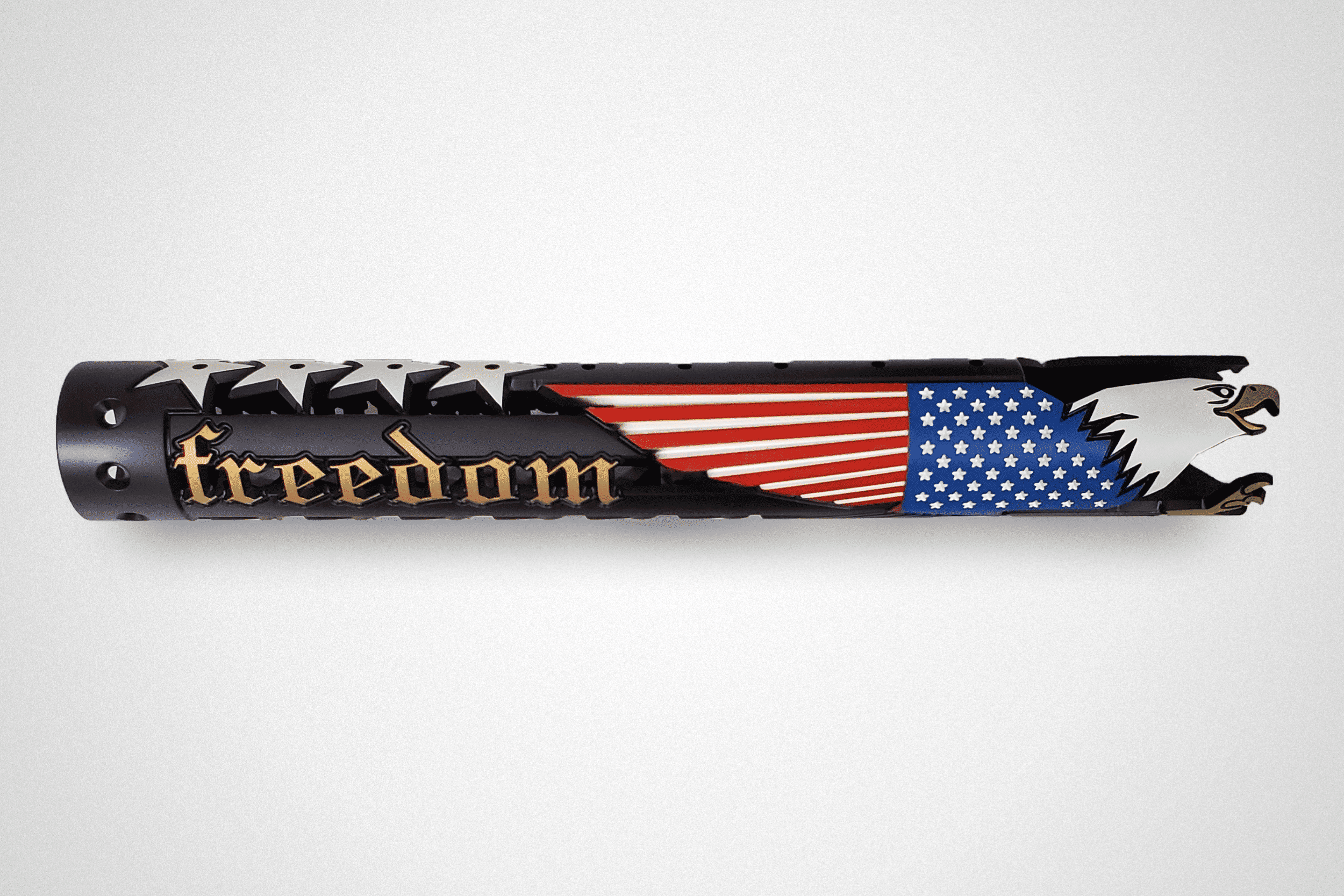

Freebird

Let freedom PIINNG! Includes barrel nut and mounting screws.

When this item is backordered, please allow 2 – 3 weeks for processing.

.When purchasing Picatinny rail for the 15″ Freedom handguard an 11.5″ Picatinny rail would be full length for the top, and on a 12″ Freedom handguard an 8.5″ Picatinny rail would be full length for the top. Not compatible with Short Shields or Sprocket End Caps.

$435.00 – $460.00